Resource description:

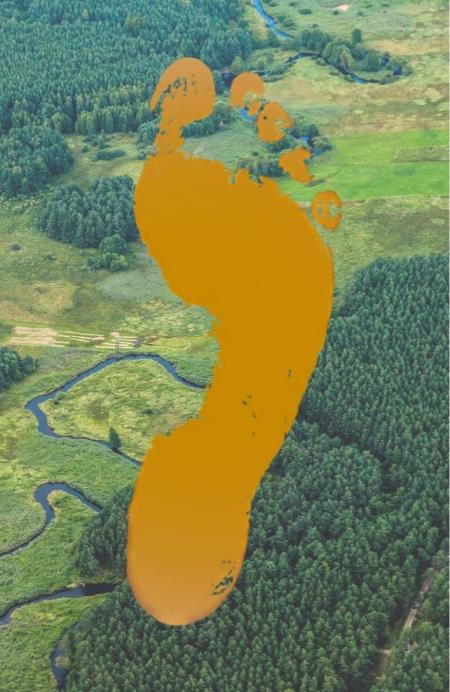

It has been identified that the woodworking industry in Ukraine is a significant sector of the economy that contributes to the sustainable development of the country, ensuring the sustainable use, reproduction, and conservation of natural resources, particularly forests. It has been established that the production of furniture panels requires significant volume of forest resources and at the same time has a substantial impact on the environment. It's require effective methods to assess such an impact. It was found that applying the ecological footprint methodology is appropriate for assessing the environmental impact of woodworking enterprises. This approach enables consideration of all factors contributing to negative environmental impacts and serves as an effective tool for analysing the environmental consequences of furniture board production. The article focused on the practical aspects of applying the ecological footprint calculation methodology using a woodworking enterprise as a case study. The impact of the enterprise's production and economic activities on the environment was assessed, including greenhouse gas emissions, water and energy consumption, and wood waste generation. This approach provides a comprehensive understanding of the environmental consequences at each stage of the production process. The ecological footprint of the processes of wood harvesting, raw material transportation, electricity generation for technological equipment operation and lighting, and thermal energy for drying blanks and heating premises, which have the greatest environmental impact, was determined. According to the calculations, the ecological footprint of producing 1 m³ of furniture boards is 0.475 ha or 95 ha of forestland to offset the negative impact of the average monthly production of furniture boards at the enterprise. It was established that to offset the negative impact of producing fuel briquettes and pellets from the main production's waste, 17.76 ha of forested land is required, for heating premises – 34.86 ha, and for generating electricity for lighting office premises – 0.016 ha. The water consumption for the production and internal needs of the enterprise amounts to 100 m³ per month. To reduce the ecological footprint, it is necessary to optimize production processes, switch to renewable energy sources, improve the efficiency of raw material use, and reduce water consumption through the implementation of water reuse systems. The research results are crucial for developing strategies to reduce the environmental impact of woodworking enterprises, enhance their environmental and social responsibility, and improve their competitiveness in the context of Ukraineʼs integration into the European Union. This contributes to addressing most pressing modern challenges and achieving sustainable development goals.

Author/Contact:

O. Kiyko | M. Ilkiv | O. Pelyukh | I. Soloviy | T. Chelepis | V. Lavnyy | D. Savka | A. Lutsenco