Objective:

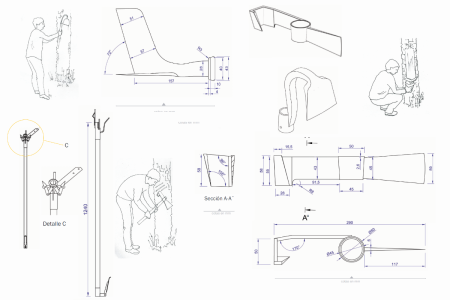

The data sheets constitute a small technical manual with the precise information so that traditional blacksmiths and small metallurgical workshops can make the tools used in Europe in the work of resin tapping using the method of bark chipping with stimulation, also known as American method.

Context:

The most widespread method of resin tapping in Europe is the so-called bark chipping with stimulation.

It is a highly specialised forestry work based on the precise making of narrow horizontal incisions on the tree trunk, sectioning the resin channels in the most superficial part of the sapwood.

Resin tools are also specialised tools that can be made in a traditional blacksmith's workshop, but most local blacksmiths are unaware of the design and manufacturing parameters of such tools.

Contacts:

Javier Calvo-Simón, javier.calvo@cesefor.com

Further information:

https://www.sust-forest.eu/