Objective:

In the life cycle of cork, carbon dioxide (CO2) and methane (CH4) gases are released from biological material combustion or decomposition as well as from burning fossil fuels. The biogenic carbon emissions from forest-based products are usually not included because they are released into the atmosphere during the processing and end-of-life stages. The carbon footprint for the cork sector should be considered at different stages, from forest management activities, across the manufacturing processes and product distribution, to the product end-of-life.

Context:

Cork oaks are age-long trees that retain biogenic carbon in their components (e.g. wood, leaves). Portugal has a large forest cover of this species and is a leader in cork production and processing. Recent studies have focused on the carbon footprint of this sector, computing the greenhouse gases (GHG) emission from the forest to the product’s end-life.

To evaluate the life cycle assessment (LCA), two approaches can be considered: static LCA (sLCA), where all emissions occur simultaneously and is not the reality of GHG emissions, or dynamic LCA (dLCA), involving varying emissions over time.

Contacts:

Joana Amaral Paulo, joanaap@isa.ulisboa.pt, https://fenix.isa.ulisboa.pt/qubEdu/homepage/isa114126/

Sónia Pacheco Faias, soniapf@isa.ulisboa.pt

Further information:

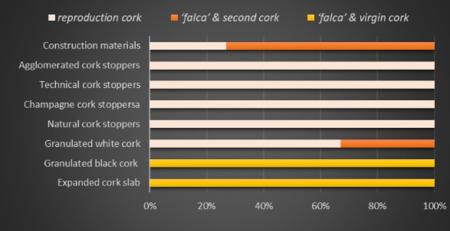

Demertzi M, Paulo JA, Arroja L, Dias AC (2016) A carbon footprint simulation model for the cork oak sector. Science of the Total Environment 566: 499–511

Demertzi M, Paulo JA, Faias SP, Arroja L, Dias AC (2017) Evaluating the carbon footprint of the cork sector with a dynamic approach including biogenic carbon flows. Int J Life Cycle 23-7:1448-1459

Demertzi et al. (2017) Environmental performance of expanded cork slab and granules through life cycle assessment. Journal of Cleaner Production 145

https://www.fct.pt/apoios/projectos/consulta/vglobal_projecto.phtml.en?idProjecto=131169&idElemConcurso=7484